Beyond the Hype: 2026 Footwear Technologies for Comfort

The latest developments on Footwear Technologies 2026, with key facts, verified sources and what readers need to monitor next in Estados Unidos, presented clearly in Inglês (Estados Unidos) (en-US).

Beyond the Hype: A 2026 Analysis of 3 Emerging Footwear Technologies for Comfort and Durability is shaping today’s agenda with new details released by industry experts and material science breakthroughs. This update prioritizes what changed, why it matters and what to watch next, in a straightforward news format.

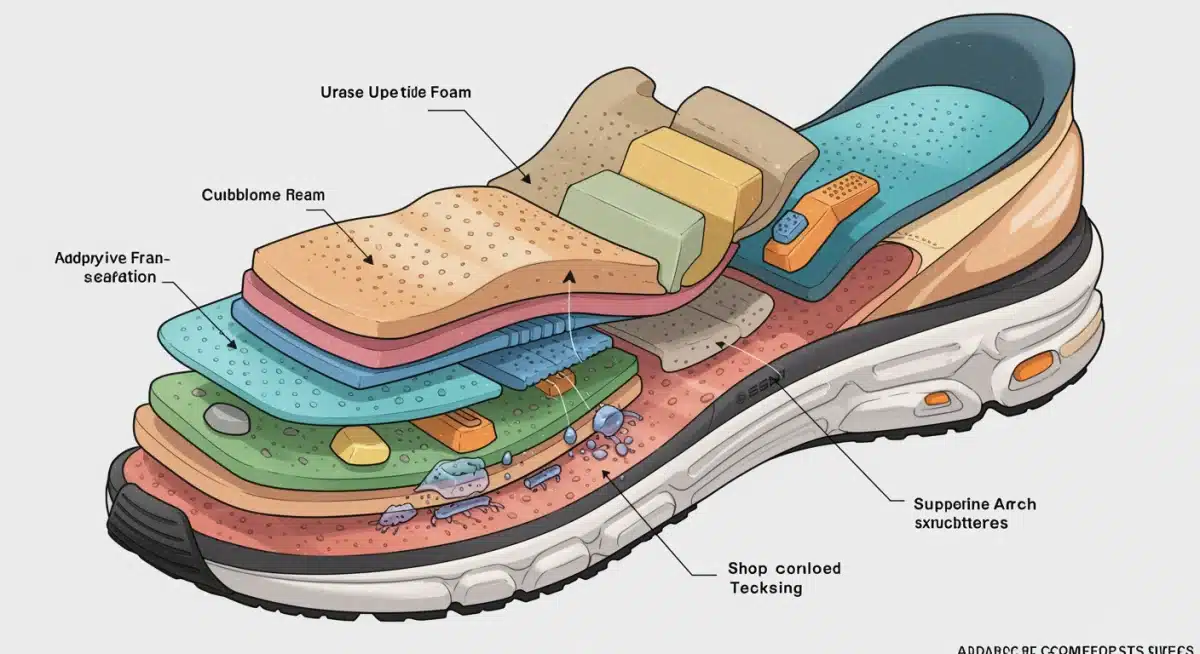

The footwear landscape is undergoing a revolutionary transformation, driven by a relentless pursuit of enhanced wearer experience. Innovations in material science and manufacturing processes are converging to create a new generation of shoes.

By 2026, these advancements will move beyond conceptual stages into mainstream applications, fundamentally altering consumer expectations. The focus remains on delivering unparalleled comfort and extending product lifespan.

The Ascent of Adaptive Cushioning Systems

Adaptive cushioning represents a significant leap forward in Footwear Technologies 2026, moving beyond static foam structures to dynamic systems that respond to individual biomechanics. These systems utilize smart materials and intricate geometries to provide personalized support and shock absorption.

The goal is to mitigate impact forces effectively, reduce fatigue, and enhance overall foot health, making every step more efficient and comfortable. This technology is particularly beneficial for athletes and individuals who spend long hours on their feet.

Current prototypes show promising results in pressure distribution and energy return, indicating a future where shoes adapt in real-time. This level of responsiveness was once a futuristic concept but is rapidly becoming a tangible reality for consumers.

Personalized Comfort Through Smart Materials

Smart materials are at the core of adaptive cushioning, featuring properties that change in response to external stimuli like pressure or temperature. These materials can stiffen or soften, redistribute impact, and even store and release energy, offering a truly dynamic wearing experience.

- Electrorheological fluids adjust viscosity under electric fields, altering cushioning on demand.

- Shape-memory polymers deform and return to their original shape, providing consistent support.

- Auxetic materials expand perpendicularly when stretched, offering unique impact absorption.

The integration of these materials allows for a level of personalized comfort previously unattainable, making shoes feel custom-made for each wearer. This represents a paradigm shift in how footwear is designed and experienced, prioritizing individual needs.

Advanced Geometry and Biomechanical Integration

Beyond material composition, the architectural design of cushioning systems plays a crucial role in their adaptive capabilities. Sophisticated geometries, often inspired by natural structures, are being engineered to maximize flexibility, stability, and energy return.

Computational design tools are now enabling the creation of intricate lattice structures and segmented soles that work in harmony with the foot’s natural motion. This approach, combined with biomechanical data, ensures optimal performance.

Manufacturers are leveraging 3D printing and advanced molding techniques to produce these complex structures with precision. The synergy between material science and structural engineering is key to the success of these emerging Footwear Technologies 2026.

Self-Healing Composites for Enhanced Durability

Durability has always been a cornerstone of quality footwear, but emerging self-healing composites are set to redefine what it means for a shoe to last. These advanced materials possess the remarkable ability to repair minor damage autonomously, significantly extending the lifespan of footwear components.

This innovation addresses common wear and tear issues, such as small tears, abrasions, and micro-cracks that typically lead to structural failure over time. The result is a shoe that maintains its integrity and aesthetic appeal for much longer.

By integrating these composites, manufacturers can offer products that are not only more resilient but also contribute to sustainability by reducing the frequency of replacements. This represents a major step forward for Footwear Technologies 2026.

Microencapsulation and Intrinsic Healing Mechanisms

Self-healing in footwear often relies on microencapsulation, where healing agents are embedded within the material in tiny capsules. When damage occurs, these capsules rupture, releasing the agents to fill and bond the compromised area.

Another approach involves intrinsic healing, where the material itself has reversible bonds that can reform upon exposure to external stimuli like heat or light. This allows for repeated repair cycles, enhancing the material’s longevity.

The development of these mechanisms is crucial for creating truly resilient footwear that can withstand daily stresses. These advancements are transforming the concept of durability, pushing the boundaries of material science.

Sustainable Impact and Consumer Value

The implications of self-healing composites extend beyond mere product longevity; they offer significant environmental benefits. By reducing the need for premature replacements, these materials decrease waste and the overall carbon footprint associated with footwear production.

Consumers also gain substantial value from shoes that last longer and require less maintenance, leading to cost savings over time. This blend of innovation, sustainability, and economic advantage positions self-healing composites as a key trend in Footwear Technologies 2026.

Smart Textiles with Integrated Sensors

The integration of smart textiles with embedded sensors is revolutionizing the functionality of footwear, offering unprecedented insights into wearer activity and comfort levels. These textiles can monitor various physiological and kinetic data points, transforming shoes into intelligent wearables.

From tracking foot pressure and gait analysis to monitoring temperature and moisture, smart textiles provide a wealth of information that can be used to optimize performance and prevent injuries. This data is wirelessly transmitted to connected devices for analysis.

This technology is particularly impactful for athletic performance monitoring, health tracking, and the development of personalized fitness regimes. The future of footwear is undeniably intertwined with these intelligent fabrications.

Real-Time Data for Performance Enhancement

Smart textiles in footwear can capture real-time data on gait mechanics, foot strike patterns, and pressure distribution. This detailed information allows athletes to refine their technique, identify imbalances, and prevent overuse injuries.

- Pressure sensors map foot contact points, optimizing running form.

- Accelerometers track speed and cadence, providing comprehensive activity metrics.

- Temperature and humidity sensors manage microclimate within the shoe, enhancing comfort.

Coaches and trainers can leverage this data to create highly personalized training programs, maximizing efficiency and minimizing recovery time. This level of data-driven insight is a game-changer for athletic footwear.

Health Monitoring and Ergonomic Design

Beyond sports, smart textiles offer significant potential for health monitoring and ergonomic design in everyday footwear. Sensors can detect subtle changes in gait that might indicate underlying health issues, providing early warnings for conditions like diabetes or neurological disorders.

The data collected can also inform the design of future footwear, leading to more ergonomically sound products that cater to a wider range of foot types and activities. This proactive approach to health and comfort is a hallmark of evolving Footwear Technologies 2026.

The continuous feedback loop created by smart textiles enables a dynamic interaction between the wearer and their footwear. This fosters a new era of personalized care and optimized performance, ultimately enhancing quality of life.

Manufacturing Advancements and Customization

The rise of advanced manufacturing techniques, such as additive manufacturing (3D printing) and robotic automation, is propelling the customization capabilities of Footwear Technologies 2026. These methods allow for unprecedented design freedom and precision in production.

Consumers can look forward to footwear that is not only tailored to their specific foot dimensions but also designed to meet their unique performance and aesthetic preferences. This shift moves beyond mass production towards highly personalized products.

The ability to rapidly prototype and produce complex geometries efficiently means that innovative designs can reach the market faster. This agility is critical in a fast-paced industry driven by evolving trends and consumer demands.

3D Printing for Bespoke Footwear Components

3D printing is transforming the way shoe components are designed and manufactured, enabling the creation of intricate lattice structures and customized sole geometries. This technology eliminates the need for traditional molds, reducing waste and lead times.

It allows for the precise placement of materials with varying properties, optimizing cushioning, support, and flexibility exactly where needed. This level of customization ensures a perfect fit and enhanced performance for every wearer.

From midsoles to outsoles and even entire uppers, 3D printing is paving the way for truly bespoke footwear. This manufacturing revolution is a cornerstone of advanced Footwear Technologies 2026, offering unparalleled personalization.

Robotics and Automated Assembly Lines

Robotic automation is streamlining the assembly process, ensuring consistency and efficiency in footwear manufacturing. Robots can perform intricate tasks with high precision, from cutting and stitching to bonding and finishing, reducing human error and labor costs.

This automation allows for greater scalability while maintaining high quality standards, even for complex designs. The integration of AI in these systems further optimizes production flows and quality control.

The combination of 3D printing and robotic assembly facilitates the mass production of customized footwear, making advanced technologies accessible to a broader market. This efficiency is vital for the widespread adoption of new Footwear Technologies 2026.

Sustainability in Footwear Innovation

Sustainability is no longer a peripheral concern but a central driver in the development of Footwear Technologies 2026, influencing material selection, manufacturing processes, and end-of-life considerations. The industry is actively seeking ways to minimize its environmental footprint.

Innovations are focusing on biodegradable materials, closed-loop recycling systems, and energy-efficient production methods to create a more eco-conscious product lifecycle. This commitment reflects growing consumer demand for responsible consumption.

From plant-based leathers to recycled ocean plastics, the range of sustainable materials is rapidly expanding, offering viable alternatives to traditional resource-intensive options. This shift is critical for the industry’s future.

Circular Economy Principles in Design

Design for circularity is becoming a guiding principle, emphasizing materials that can be easily disassembled, recycled, or biodegraded at the end of the shoe’s life. This approach aims to keep materials in use for as long as possible, reducing waste.

- Modular designs allow for easy replacement of worn-out components, extending product utility.

- Single-material construction simplifies recycling processes, promoting resource recovery.

- Biodegradable polymers decompose naturally, minimizing landfill impact.

Companies are investing in research and development to create materials that maintain performance while adhering to strict environmental standards. This holistic approach ensures sustainability from conception to disposal.

Reduced Environmental Impact Throughout Production

Beyond materials, manufacturing processes are being re-evaluated to reduce energy consumption, water usage, and chemical waste. Innovations like waterless dyeing techniques and solvent-free adhesives are gaining traction.

Localization of production and optimized supply chains also contribute to a lower carbon footprint by minimizing transportation emissions. These efforts collectively aim to create a more environmentally responsible footwear industry.

The integration of sustainable practices across the entire value chain is crucial for the long-term viability of Footwear Technologies 2026. This commitment ensures that innovation goes hand-in-hand with environmental stewardship.

The Future of Footwear: A Seamless Experience

The convergence of adaptive cushioning, self-healing composites, and smart textiles points towards a future where footwear offers a truly seamless and intuitive experience. Shoes will not just be worn; they will actively engage with and respond to the wearer’s needs.

Imagine shoes that adjust their cushioning based on your activity, repair themselves overnight, and provide real-time health insights, all while being sustainably produced. This vision is rapidly becoming a reality for Footwear Technologies 2026.

This holistic approach to footwear design and functionality promises a new era of comfort, durability, and personalized performance. The industry is moving towards products that are inherently smarter, more resilient, and deeply integrated into our daily lives.

Market Adoption and Consumer Trends

The adoption of these advanced Footwear Technologies 2026 will be driven by a combination of technological maturity, consumer demand, and strategic marketing. Early adopters are already seeking out products that offer superior comfort and longevity.

As production costs decrease and awareness grows, these innovations are expected to penetrate mainstream markets, becoming standard features rather than niche offerings. Brands that successfully integrate these technologies will gain a significant competitive edge.

Consumer trends indicate a growing preference for products that offer both high performance and environmental responsibility. This alignment of technological advancement with ethical considerations will accelerate market adoption.

| Key Technology | Core Benefit |

|---|---|

| Adaptive Cushioning | Personalized comfort and superior shock absorption. |

| Self-Healing Composites | Extended footwear lifespan and reduced waste. |

| Smart Textiles | Real-time data for performance and health monitoring. |

| Advanced Manufacturing | Bespoke designs and efficient, sustainable production. |

Frequently Asked Questions About Footwear Technologies 2026

Adaptive cushioning systems offer personalized comfort by dynamically adjusting to an individual’s biomechanics. They provide superior shock absorption, reduce fatigue, and enhance overall foot health, leading to a more efficient and comfortable wearing experience during various activities.

Self-healing composites extend footwear durability by autonomously repairing minor damages like tears and abrasions. This capability significantly prolongs the lifespan of shoes, reduces the need for frequent replacements, and contributes to environmental sustainability by minimizing waste from discarded footwear.

Smart textiles integrated into footwear can collect a wide range of data, including foot pressure distribution, gait analysis, temperature, and moisture levels. This real-time information is invaluable for optimizing athletic performance, monitoring health, and developing personalized fitness and wellness routines.

Initially, advanced Footwear Technologies 2026 may carry a premium price. However, as manufacturing processes become more efficient and economies of scale are achieved, these innovations are expected to become increasingly accessible and affordable for the average consumer, similar to other technological adoptions.

These technologies significantly enhance sustainability. Self-healing materials reduce waste by extending product life, while advanced manufacturing minimizes resource consumption. Additionally, the focus on biodegradable materials and circular economy principles ensures a smaller environmental footprint for the next generation of footwear.

Looking Ahead

The analysis of Footwear Technologies 2026 reveals a transformative period for the industry, emphasizing innovation in comfort and durability. It is crucial for consumers and industry stakeholders to monitor ongoing research, product launches, and regulatory developments closely. These advancements are not merely incremental improvements; they represent a fundamental shift in how footwear is conceived, produced, and experienced, promising a future where shoes are smarter, longer-lasting, and more attuned to individual needs.